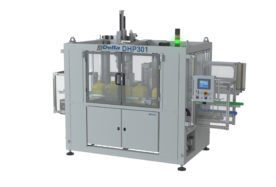

DHP301

Handle applicator

Need

When blow moulding big bottles (> 2L) by the two-stage process, it is impossible to blow a handle into the bottle itself. Therefore, instead of blown handles, you can use external plastic handles. A handle applicator applies these to the bottles.

(In the one-stage process, on the other hand, you can inject the handle immediately into the preform. And for smaller bottles, the deep grip technology is available as well.)

However, the traditional way of injection moulding external handles gives rise to many problems.

For example: When producing handles in bulk, the operator often has to cram many handles into a box in a disorderly way, when the plastic has not even cooled down yet. This often results in warping, shrinkage or deformation of the handles. Consequently, this causes line stoppages, jams, etc. At least, this is the case with conventional handle applicators.

Therefore, in order to prevent this, we at Delta Engineering designed this handle applicator in such a way that the handles are stackable!

The machine

The DHP301 is a fully automatic, single head handle applicator for bottles.

Completely servo-driven. Speed: around 800 – 1200 BPH.

Thanks to its design, it is one of the most compact handle applicators available, because we get rid of the handle unscrambler.

ADVANTAGES

Our revolutionary stackable handle design has many advantages:

– On the injection side:

-

- The injection moulding robot can stack the handles in piles directly, without the need for human supervision.

- The stacking avoids that the handles are tumble packed. As a result, we prevent deformation.

- By stacking, the handles can still be warmer without the risk of deforming. This means that the handle applicator can run faster, because the stacks can cool down quietly afterwards.

- Once it reaches the desired number of handles, the conveyor indexes and the stacking can restart. As a result, you save on labour.

- Moreover, more piles of stackable handles fit into a box. No waste of space, so you also save on package and transportation costs.

– On the blowing side:

-

- The piles of handles run into the machine on a handle infeed conveyor. This allows you to place 10-20 piles of 30-60 handles each into the machine.

- Thanks to this, the autonomy of the handle applicator is typically between 30-60 minutes. Piles of handles can be added without stopping the machine.

- Then, the machine unstacks the piles and applies the handle to the bottle. The applicator head supports the bottle internally when applying the handle. Consequently, this avoids the bottle crashing, which can otherwise occur when applying handles to warm HDPE bottles in bottle production environments.

COMPONENTS

- Bottle in/outfeed conveyor

- Handle infeed conveyor

- Handle applicator head

The infeed conveyor can be any type: chain or flat belt.

Delta Engineering can supply you with the handles as well. One of our partners designs them. The development of a handle requires a high sense of detail, so profit from our experience!

RELATED

Stackable handle grabbing tool: DHP010