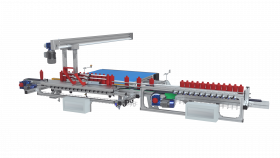

DRF100

Row forming unit

Need

When packaging bottles, sometimes you have bottles that cannot accumulate. In case the conicity is on one side only, we might still get away with our Rotary wheel. This is available on most of our machines.

However, when bottles are conical on all sides, you can either go with pucks or use the row forming unit. This unit is integrated into the machine itself and is more cost effective than Puck lines.

Design

The row forming unit stops each bottle independently with a dedicated micro stopper. These stoppers are easily adjustable sideways, to allow different bottles / packing formats.

As the bottles are running into the machine, each stopper ‘grabs’ a bottle, without touching the other ones.

In this way, we can build up a row, without the bottles physically touching each other.

Then, the machine pushes the row onto the packing machine belt, to allow collation. This works with a belt only, not with a plate. Therefore, it is only suitable for machines equipped with this.

The row forming unit is embedded in the machine as well. So you cannot transfer it to another machine.

Advantages

- Allows the handling of difficult bottles

- Easily adjustable

- Lower cost than Puck system

Note: limited to single lane systems & push-on-belt-machines.