EBM

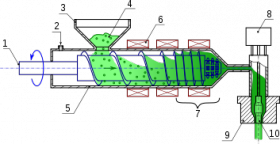

In Extrusion Blow Moulding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected.

- Published in Process

IBM

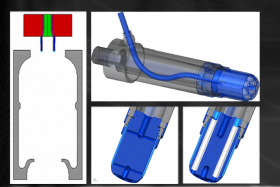

The process of injection blow molding (IBM) is used for the production of hollow glass and plastic objects in large quantities. In the IBM process, the polymer is injection molded onto a core pin; then the core pin is rotated to a blow molding station to be inflated and cooled. This is the least-used of the three blow molding processes, and is typically used to make small medical and single serve bottles. The process is divided into three steps: injection, blowing and ejection.

- Published in Process

Importance of the blowing pressure

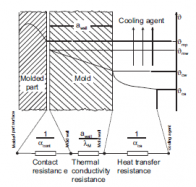

This article describes a test setup in a theoretical model to measure the impact of the flushing air, and evaluating the cost of the compressed air against the cooling coefficient gain.

- Published in Heat transfer in blow molding

Importance of the surface

In blow molding the blowing pressure is extremely important. An article from the University of Aachen with a theoretical model on the importance of the pressure in function of the surface geometry.

- Published in Heat transfer in blow molding

Injection

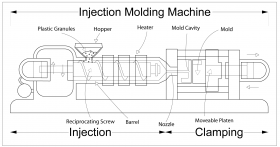

Injection moulding (injection molding in the USA) is a manufacturing process for producing parts by injecting material into a mould. Injection moulding can be performed with a host of materials, including metals, (for which the process is called diecasting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers.

- Published in Process

ISBM

This has two main different methods, namely Single-stage and two-stage process. Single-stage process is again broken down into 3-station and 4-station machines In the two-stage injection stretch blow molding ( ISBM ) process, the plastic is first molded into a “preform” using the injection molding process. These preforms are produced with the necks of the bottles, including threads (the “finish”) on one end. These preforms are packaged, and fed later (after cooling) into a reheat stretch blow molding machine. In the ISB process, the preforms are heated (typically using infrared heaters) above their glass transition temperature, then blown using high-pressure air into bottles using metal blow molds. The preform is always stretched with a core rod as part of the process.

- Published in Process

Online or offline labeling in extrusion blow molding

Labeling behind blow molding machines can result in a bubbled surface of the label, due to bottle shrinkage. There are different techniques to improve / solve these problems.

- Published in Process