Bagging : Perfect welding of bagged bottles in pharmaceutical or food environments

- Published in Bagging

Bottle trimming whitepaper

Machines

Adjustment, process and design instructions for the following Delta Engineering Trimming machines :

DC100

DC150

These machines are designed for the trimming of jars with ROUND openings.

- Published in Trimming

Check weighing

A checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

- Published in Check Weighing

Easy film change on bagging machines

Delta Engineering developed some new bagging tools : A simple tool to add on existing machines, allowing you more easy to position the base film roll during film change operations. A carriage who allows you to store a couple of rolls, together with a welding system. Interested ? Please contact our sales department per email

- Published in Bagging

EBM

In Extrusion Blow Moulding (EBM), plastic is melted and extruded into a hollow tube (a parison). This parison is then captured by closing it into a cooled metal mold. Air is then blown into the parison, inflating it into the shape of the hollow bottle, container, or part. After the plastic has cooled sufficiently, the mold is opened and the part is ejected.

- Published in Process

Flat plastic sheets

Returning packaging solutions – Flat plastic sheets Over the years, we have developed together with our partners different packaging solutions for our customers, mainly focusing on returnable packing solutions because they have in most cases a fairly high return on investment. The first one we are discussing in this article is ‘ Returnable plastic flat

- Published in Flat sheet

HDPE

High-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a polyethylene thermoplastic made from petroleum. It is sometimes called “alkathene” or “polythene” when used for pipes. With a high strength-to-density ratio, HDPE is used in the production of plastic bottles, corrosion-resistant piping, geomembranes, and plastic lumber. HDPE is commonly recycled, and has the number “2” as its resin identification code (formerly known as recycling symbol).

- Published in Raw material

High Speed bagging – Redundant line design

Redundant line design is very important if a highly efficient line is wished for. This article is about a high speed PET bagging line, witch is designed in this way. We will discuss the OEE definition and practical interpretations, advantages of bagging and , pallet stability, last but not least the line concept in detail.

- Published in Bagging

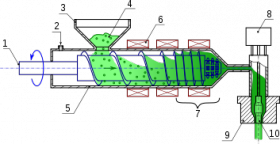

IBM

The process of injection blow molding (IBM) is used for the production of hollow glass and plastic objects in large quantities. In the IBM process, the polymer is injection molded onto a core pin; then the core pin is rotated to a blow molding station to be inflated and cooled. This is the least-used of the three blow molding processes, and is typically used to make small medical and single serve bottles. The process is divided into three steps: injection, blowing and ejection.

- Published in Process

Importance of fume extraction when spray coating plastic bottles or preforms

Spray coating Spray coating is a technology used to coat the surface of the bottle to improve the sliding and brightness properties of the treated bottles. This is a very effective method in comparison to additives inside the bottles or preforms, as it doesn’t affect the material properties. Often , additives have an impact on

- Published in Coating