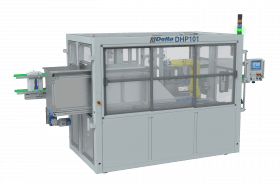

DHP101

Spout applicator

Completely robotic-driven.

Speed: around 500 – 800 BPH.

How does it work?

The spouts are dropped onto a bulk conveyor, and collated towards a vision system. The vision system recognises the spouts in 3D using bin picking technology.

Then, it transfers the coordinates to the robot, which picks the targeted spout and inserts it into the drum.

Besides the recognition of the spouts, the machine can also disregard deformed spouts, in order to avoid line jams. As a result, this allows full flexibility and is easy to operate for the operators.

Thanks to its design, the spout applicator is very compact, because we get rid of the spout unscrambler.

Moreover, it is equipped with a spout presence check, rejecting drums in which the spout is not present.

Depending on the spout design, the machine can run approximately 1 hour without operator intervention.

Need

Today’s AdBlue market requires a lot of 5L, 10L & 20L plastic packaging. For easy pouring, a spout is integrated into the drum.

Both container and spout are made on separate machines at separate cycle times.

Because manual insertion is very labour-intensive and expensive, we have developed this vision-controlled spout applicator.

ADVANTAGES

- Low floor space usage because the spout applicator does not need an unscrambler.

- Configurable left – right infeed to suit your needs.

- Bad or deformed products do not lead to a line stop but are disregarded.

- Reject bin for non-inserted and deformed products.

- 250L bin for spouts, which allows the storage of 300-600 spouts, depending on the design.

We can support you in the spout designing process as well, so benefit from our experience!

RELATED MACHINES

Handle applicator for bottles (without handle unscrambler): DHP301

Handle applicator for bottles (with handle unscrambler): DHP200