There is always something new to be experienced at Delta Engineering. Whether it is a new development or upgrades on

existing machines in close cooperation with our customers.

Do you want to be up to date? Select one of the topics below for more detailed information:

| Exhibition | Drinktec |

| Dates | September 15th – 19th, 2025 |

| Exhibition space | Hall C6, booth 553 |

| Location | Messe München, Germany |

| Exhibition | K-2025 |

| Dates | October 8th – 15th, 2025 |

| Exhibition space | Hall 14, booth A08 |

| Location | Messe Düsseldorf, Germany |

April 2024

Customer testimonial Califia Farms in PETplanet magazine

We are thrilled to share a customer testimonial from Califia Farms in PETplanet Insider magazine, highlighting their positive experience working with Delta Engineering. According to Califia Farms, “Delta Engineering helps smooth the flow and boost efficiency of new bottle blowing lines”.

Califia Farms, a renowned American manufacturer of plant-based drinks, invested in automation to save time and reduce costs and carbon emissions. As part of their transformation, Califia Farms transitioned from using pre-blown bottles to blowing their own bottles from preforms on-site, a project supported by Delta Engineering.

In reflecting on their collaboration with Delta Engineering, Califia Farms praised Delta Engineering for being “responsive, professional, and a joy to work with. They worked hard to ensure that everything was right before we installed their equipment. Their equipment is high quality and I attribute a large proportion of the project’s success to them.”

We are very grateful for these warm words and for the opportunity to have contributed to Califia Farms achieving their goals of reducing costs, eliminating over 830 million tons of CO2 from their supply chain, having a greater security of bottle supply, and cutting inward truck movements by 90%.

April 2020

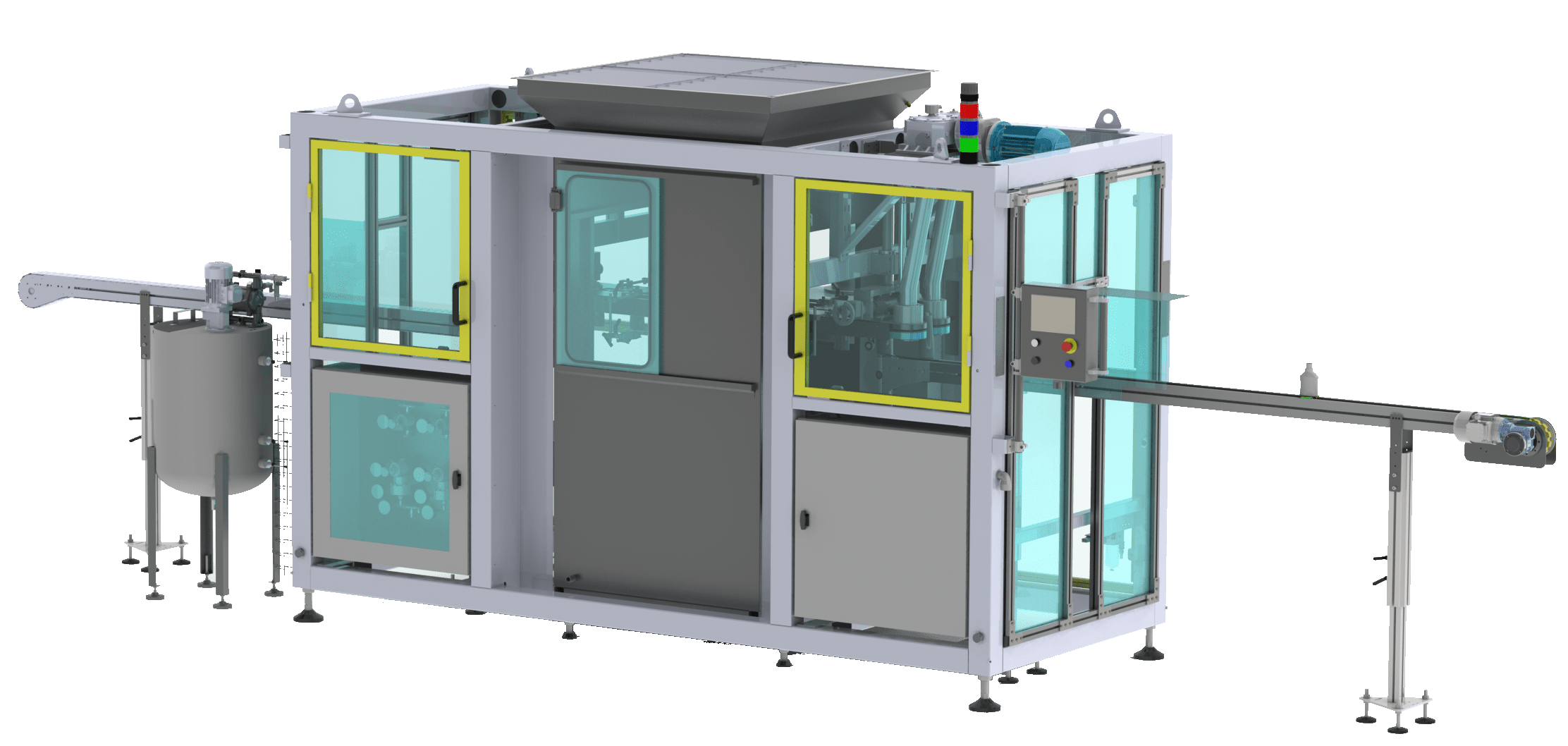

PLASMA COATING BRANCHES OUT

Plasma coating, which has long been used to treat the surfaces of beverage bottles, isn’t just

for soft drink companies anymore. The method, which can be used to improve the gas barrier of

PET bottles, also offers benefits when it comes to manufacturing HDPE products and big

containers.

The Technology

Plasma is one of the four states of matter, along with solid, liquid and gas. Delta

Engineering’s new coating machines preform plasma-enhanced chemical vapor deposition (PECVD).

Advantages of Plasma Coating

Plasma coating is a viable alternative to multilayer technology, offering a variety of benefits.

Compared with multilayer technology, it’s more cost-effective and also sustainable from an

environmental perspective.

Coating technologies make recycling more efficient and effective, an essential step toward a

circular economy.

Click here to read the article.

December 2019

UDK450 INTEGRATED IN 1 BLOW 2LO MACHINE

Incorporation of Delta Engineering’s UDK 450 leak-detection system within the machine. The

optional system uses a state-of-the-art, high-voltage system to rapidly and automatically detect

and reject containers with microcracks.

Benefits

Cost and space savings. Incorporating the leak-detection system within the machine’s frame saves

space and is less expensive than buying the system separately.

Click here to read the article.

May 2018

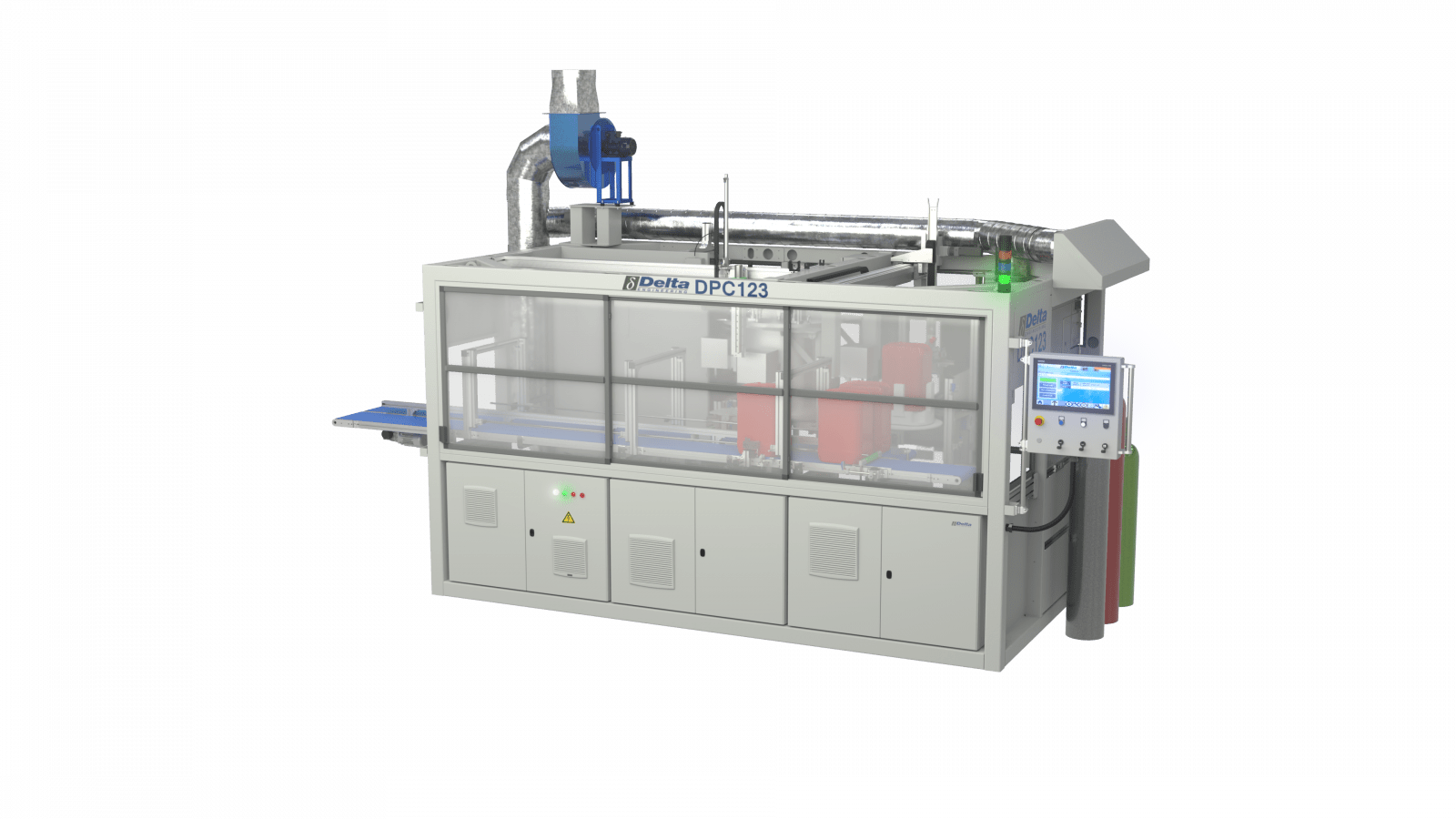

DELTA OFFERS SPRAY COATING UNIT

Delta Engineering’s new spray coater applies a light coating to bottles to address several

issues that often affect PET bottles on filling lines. Bottles enter on a conveyor, then are

grabbed by the neck and misted with an anti-static coating before the dry bottles are returned

to the conveyor to exit the machine at a rate of about 8,000 bottles per hour.

What’s new?

The machine, which is making its North American debut at NPE2018.

Benefits

Improved product quality and smoother production operations. Bottles treated by the coater are

less likely to get stuck between guides, have improved brightness, fewer scuff marks and less

static. Users can quickly and easily make adjustments to accommodate different types of bottles.

Also, the machine’s new spray process is efficient, reducing coating consumption.

| Exhibition |  |

| Dates | September 24th – 26th, 2024 |

| Exhibition space | Hall 6, booth 102 |

| Location | Nürnberg Exhibition Center, Nürnberg, Germany |

| Exhibition |  |

| Dates | October 7th – 9th, 2024 |

| Exhibition space | #62 |

| Location | Crowne Plaza Atlanta SW, Peachtree City, GA, USA |

| Exhibition |  |

| Dates | November 5th – 7th, 2024 |

| Exhibition space | Booth Z1-18 |

| Location | Dubai World Trade Center, Dubai, United Arab Emirates |

| Exhibition |  |

| Recap of event | Recap video NPE2024 |

| Dates | May 6th – 10th, 2024 |

| Exhibition space | S17061 – South Hall |

| Location | Orlando, FL, USA |

| Register |

|

| Add to ‘MyNPE’ |

|

| Exhibition |  |

| What will we show? | Live demonstrations of a complete line: bottle production (Tahara EBM machine), quality control (Delta UDK481: 4-in-1 top load tester & pressure decay leak tester & high voltage leak tester & bottle height measuring system) & packaging (Delta DB112 automatic bagger) |

| Dates | 28th November – 2nd December 2023 |

| Exhibition space | Hall 7, booth 72712 – next to Tahara’s booth |

| Location | Makuhari Messe, Greater Tokyo Area, Japan |

| Exhibition |  |

| Dates | 23rd – 25th October 2023 |

| Exhibition space | #59 |

| Location | Chicago, IL, USA |

| Event | Open House at Delta Engineering: Blow Moulding |

| Who should attend? | Companies active in the blow moulding industry. | Dates | 26 – 28 September 2023 |

| Location | Delta Engineering (R&D centre) Parkbos 6 9500 Ophasselt BELGIUM |

| How to register? |

|

| What? | During this Open House event at Delta Engineering, you will get the opportunity to:

|

| Event | Open House at Delta Engineering: Plasma – Filling – Agrochemical – Tubes – Thermoforming |

| Who should attend? |

|

| Dates | 19 – 21 September 2023 |

| Location | Delta Engineering (R&D centre) Parkbos 6 9500 Ophasselt BELGIUM |

| How to register? |

|

| What? | During this Open House event at Delta Engineering, you will get the opportunity to:

|

| Exhibition |  |

| Dates | 11th – 13th September 2023 |

| Exhibition space | N-9262 |

| Location | Las Vegas, NV, USA |

| Register | You’re invited to attend for free, register here |

| Exhibition |  |

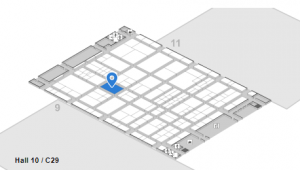

| Dates | 4th – 10th May 2023 |

| Exhibition space | Hall 10 / booth C29 (co-exhibiting with Flanders Investment & Trade) |

| Location | Messe Düsseldorf, Germany |

| Exhibition |  |

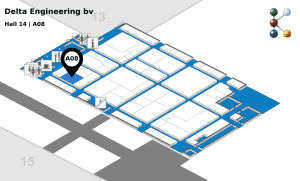

| Dates | 19th – 26th October 2022 |

| Exhibition space | Hall 14 / A08

|

| Location | Messe Düsseldorf, Germany |

| Exhibition |

|

| Dates | 12th – 14th September 2022 |

| Exhibition space | Booth #23 |

| Location | Loews Philadelphia Hotel | PA, USA |

| Official website | blowmoldingdivision.org/ |

| Event | Open House: 30 Years of Delta Engineering at our headquarters in Belgium |

| Dates | 27 June – 1 July 2022 |

| What? | Open House at Delta Engineering, with live machine demos, presentations by many companies on the latest developments in the industry, plenty of networking opportunities…

|

| Location | Delta Engineering’s R&D centre at our headquarters in Ophasselt, Belgium |

| Event | Delta Engineering at the ASB Open House in Atlanta, GA |

| Recap of event | Recap video ASB Open House |

| Dates | 24-26 May 2022 |

| What? | During this Open House organised by Nissei ASB, Delta Engineering had fully operational machines on display, fully integrated with the ASB blow molding machines along with auxiliary equipment. Check out the agenda and the different machines in action in the attached document. |

| Location | The ASB Technical Support Center in Atlanta, GA 1375 Highlands Ridge RD SE Smyrna, GA 30082 |

| Exhibition |  Our Sales Engineer Danny Stevens is also guest speaker: Plasma coating – a customer case study (Tuesday 12 October at 4.30pm) |

| Dates | 11th – 13th October 2021 |

| Exhibition space | Booth #49 |

| Location | Crowne Plaza Atlanta Perimeter at Ravinia | Atlanta, GA – United States |

| Official website | blowmoldingdivision abc 2021 overview |

| Event |  |

| Consul General of Belgium in Atlanta visits Delta Engineering Inc |

| Exhibition |  |

| Recap of event | Delta Engineering at NPE |

| Dates | 7 – 11th May 2018 |

| Exhibition space | S18058 |

| Location | Orlando, Florida USA |

| Event |  |

| Belgian delegation in our offices from Atlanta |

Click here to read the article

Click here to read the article