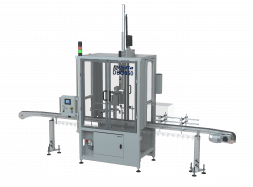

DBO050

Pneumatic bottle orientor

Need

Bottle orientors serve multiple purposes:

– On the blow moulding side:

HDPE bottles are made on a twin station machine, made from the same parison. Their necks are in the same direction (in the machine) for material distribution purposes. However, exiting those bottles on different sides makes them come out in different ways. As a result, joining bottles together often creates the need for rotating stations. For this reason, we at Delta Engineering developed different solutions, the DBO050 being the simplest one.

The bottle orientor grabs the bottles by the body, and rotates them by using pneumatic cylinders. The orientation stroke is adjustable.

In most cases, a simple orienting system (DBO050) is sufficient, but if necessary we can quote the high-speed flexible bottle orientor DBO100, embedded in a security – safety fenced solution.

For OEM customers, we have integrated solutions as well (without safety fencing).

Moreover, on the DBO100, we can provide a smart camera to detect the actual orientation of the bottle and correct to the desired orientation. This can be very useful on higher speed lines on which bottles are irregularly oriented. It is important to detect wrongly oriented bottles and reorient them if necessary, because they can cause line jams. By doing so, you ensure a high line OEE.

– In-between filling lines:

The same need is present on filling lines as well, but on those lines, the DBO100 is in most cases a necessity as the speeds are higher.

Machine design

This bottle orientor is a very stable and reliable orienting system. Moreover, it is integrated into a stable frame, so it ensures the latest safety standards.

ADVANTAGES

- Quick changeover, easy mechanical adjustments

- Flexible solution, handling a wide range of bottles

- Rigid construction

RELATED MACHINES

High-speed bottle orientor: DBO100