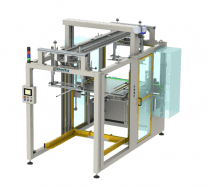

DP200

Semi-automatic bottle palletizer

Need

In today’s market where speeds go up and floorspace is precious, quick changeovers and a high level of flexibility are essential for today’s packaging equipment.

Therefore, we developed the highly flexible, semi-automatic bottle palletizer DP200.

The machine

This bottle palletizer is the most flexible packaging unit available on the market, because it can handle:

- Hoods

- Flat sheets

- Trays

- Half trays

- Stackable containers without trays

Moreover, it can also palletize a wide range of bottles.

In addition to the high flexibility in packaging methods and bottle range, it can also be switched over extremely fast.

This bottle palletizer can make pallets with the base of the top layer at maximum 1,6 m (63”), but 1,35 m standard is advised. By doing so, you can make pallets of 1,45 m high, so you can stack 2 pallets on top of each other in the lorry.

Furthermore, it can handle pallets of 1200 mm wide x 1200 mm long.

So how does this bottle palletizer work?

Firstly, it feeds the bottles in on a table top conveyor. Then, row by row, it creates a layer of bottles by pushing the rows on a stainless-steel plate. Once the layer is complete, it is pushed on top of the previous layers on the pallet. Subsequently, the pallet goes down so the top of the bottles is a little lower than the table. At that level, a slip sheet or a tray has to be placed on top of the bottles and is used as the supporting layer for the next layer of bottles. Then, the pallet rises again so the slip sheet or tray is level with the table. This continues until the pallet is complete. Finally, when the pallet is ready, it descends to floor level and can be taken out.

Additionally, we can modify the infeed section according to your needs:

- Rotary station

- Staggered infeed – adjustable stacking patterns

- Rotary wheel for oval bottles

- Ionizer to avoid static charges

ADVANTAGES

- Very flexible, as it can palletize a wide range of products on either flat sheets, trays or under hoods. So even with changing demands of the customers, you can still keep on using the same machine!

- Easy setup and short changeover times thanks to recipes

- Different stacking patterns possible

- Reduces the manual labour for packing. As a result, you get a short return on investment!

OTHER VERSIONS

Semi-automatic bottle palletizer – buffer table 1400 x 1200mm: DP201

Fully automatic bottle palletizer with integrated tray warehouse – in trays: DP240, DP252, DP263

Fully automatic drum palletizer – stackable containers: DP290, DP300

RELATED MACHINES

Pallet duplicator: DP050

How can I optimize my stacking pattern?