DP240

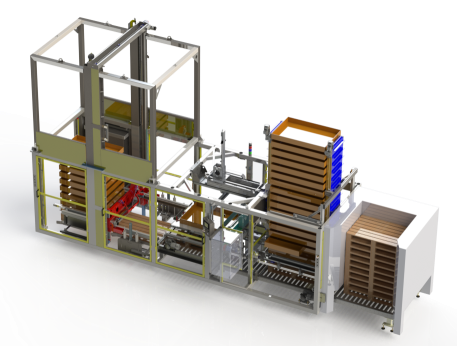

Automatic palletizer empty bottles with integrated tray warehouse

The machine

The DP240 is a compact, full automatic palletizer for empty bottles in trays.

More specifically, it can make pallets up to 3.1 m (122”) high, with trays up to 1200 x 1200 mm (48” x 48”). Since you can make full Jumbo lorry high pallets (3.1 m), you minimize transport costs!

In addition, the machine can also handle two half-size trays per layer!

Furthermore, it is a highly adjustable machine thanks to its servo movements.

So how does this automatic palletizer work?

In short, it first makes rows of bottles. Then, a servo gripper grabs the row, lifts it and sets it down on the tray. Finally, when the tray is full, it is placed onto the pallet.

The concept

Let’s have a look at how this automatic palletizer works in more detail:

- Tray stacking and dispensing

The machine comes with an integrated tray dispenser that can hold up to 15 trays of 150 mm (6”) high. From a safety point of view, we developed the machine so trays can be added while the machine is running without having to open doors.

Firstly, the tray dispenser drops a tray onto a tray conveying belt that will feed the tray to the tray filling part when requested.

- Tray filling

Secondly, the bottles are conveyed into the machine on a conveyor.

On that belt, a row of bottles is formed. Then, the servo gripper picks up the row and places it inside the tray. At each cycle, a support plate compresses the layer in the tray for optimal stacking. The automatic palletizer repeats this action until a complete layer of bottles has been finished. - Tray stacking

Subsequently, when a full layer is ready (either one or two trays consecutively), it will be transferred to a tray lift where the tray will be pushed onto a stainless-steel plate. Then, that tray lift will take the tray to the correct level and set it down.

- Pallet transport

Moreover, different pallet loading systems are availabe:

- Manual: you have to take out and put in every pallet manually

- AGV interface

- Run through, with or without pallet dispenser

- Low-level pallet conveyor for manual unloading

Options

There are other options as well.

For example, we can equip the infeed section according to your needs:

- Chain or flat belt conveyor, with or without vacuum, depending on your needs

- Bottle orienting systems, when handling oval bottles

- Puck conveyors, when running non-accumulable bottles

Additionally, this automatic palletizer has a tray warehouse in a low & high version, to store the maximum number of trays.

Optionally, film sheet placement is possible, to create a plastic layer between the bottles and the trays. By doing so, you avoid contamination!

ADVANTAGES

- Easy setup and short changeover times thanks to recipes

- Different stacking patterns possible

- Handles trays and half trays

OTHER VERSIONS

Semi-automatic palletizer – buffer table 1200 x 1200mm: DP200

Semi-automatic palletizer – buffer table 1400 x 1200mm: DP201

Fully automatic palletizer: DP252, DP263

Fully automatic drum palletizer – stackable containers: DP290, DP300

RELATED MACHINES

Pallet conveyor: CR1240

FAQ

How many bottles can I pack per hour?

How can I optimize my stacking pattern?