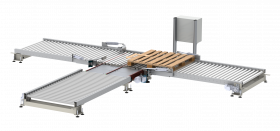

Pallet roller conveying

Pallet roller conveyor

Need

We highly recommend pallet conveying in automation, because, in addition to conveying products from point A to B, it also generates buffer.

And in production, this is a very important feature, because it allows operators to resolve problems on the stretch wrapper without affecting the production: it prevents the machines from stopping.

For this reason, it is useful to use pallet roller conveyors.

The conveying system

At Delta engineering, we have developed our own pallet roller conveyors, for different reasons.

Firstly, our rollers are close to each other, which allows us to send pallets through in any direction.

Secondly, our roller conveyors exist in different widths:

- for the USA: 1560 mm wide (machine CR1560)

- and for the rest of the world: 1240 mm wide (machine CR1240).

Typically, we divide pallet conveying sections into short sections to collect just one pallet. As a result, this allows us to accumulate pallets without touching.

Furthermore, there is a full range of possibilities:

- Side transfers

- Rotary tables

- Pallet lifters

- Strappers

- Stretch wrappers

- …

Moreover, the rollers are controlled by our DLC Line Control systems, which allow software simulation in complex systems.

Additionally, you can have this pallet roller conveyor in different shapes: L-shape, T-shape or X-shape (see ‘Machine pictures’ below).

Download our technical catalogue for more specifications.

ADVANTAGES

Can be integrated in Delta packing machines to obtain a fully automatic line.

RELATED MACHINES

Pallet dispenser: DPD250

Pallet duplicator: DP050

Palletizers with integrated roller conveyor: DP240, DP252, DP263, DP290, DP300

Pallet lift: PLM100

Pallet transfer car: DTC1240