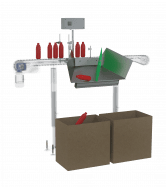

DSB010

Simple Twin Box loading unit – tumble packing

Need

Tumble packing is a widely used solution: for small bottles, or where the transport distance between the manufacturing site and filling site is not so big.

Generally, we lose 10-30 % transport volume when going from arranged packing to tumble packing, strongly depending on the bottle volume and geometry. However, it is still a viable solution for small bottles.

Therefore, we have developed the DSB010 box loading unit, which drops empty bottles into boxes, tumble packed.

The machine

You can mount this box loading unit at the end of any conveyor, suiting your needs.

One photocell counts the bottles passing by, as the unit drops them into a box.

Once the counter reaches the right number of bottles (= it reaches its ‘switch position’, which means that the box is full), a diverter flap is toggled and diverts the bottles into another, ‘empty’ box.

Then, an alarm lamp notifies the operator to replace the filled box by an empty one.

Thanks to its simple system, this unit is very budget-friendly. Moreover, it has its own control system and is completely line-independent.

ADVANTAGES

- Simple system, allowing full flexibility

- Compact floor space usage

- Simple operation

- Extremely economic solution

OTHER VERSIONS

Box tumble pack loading unit: DSB200