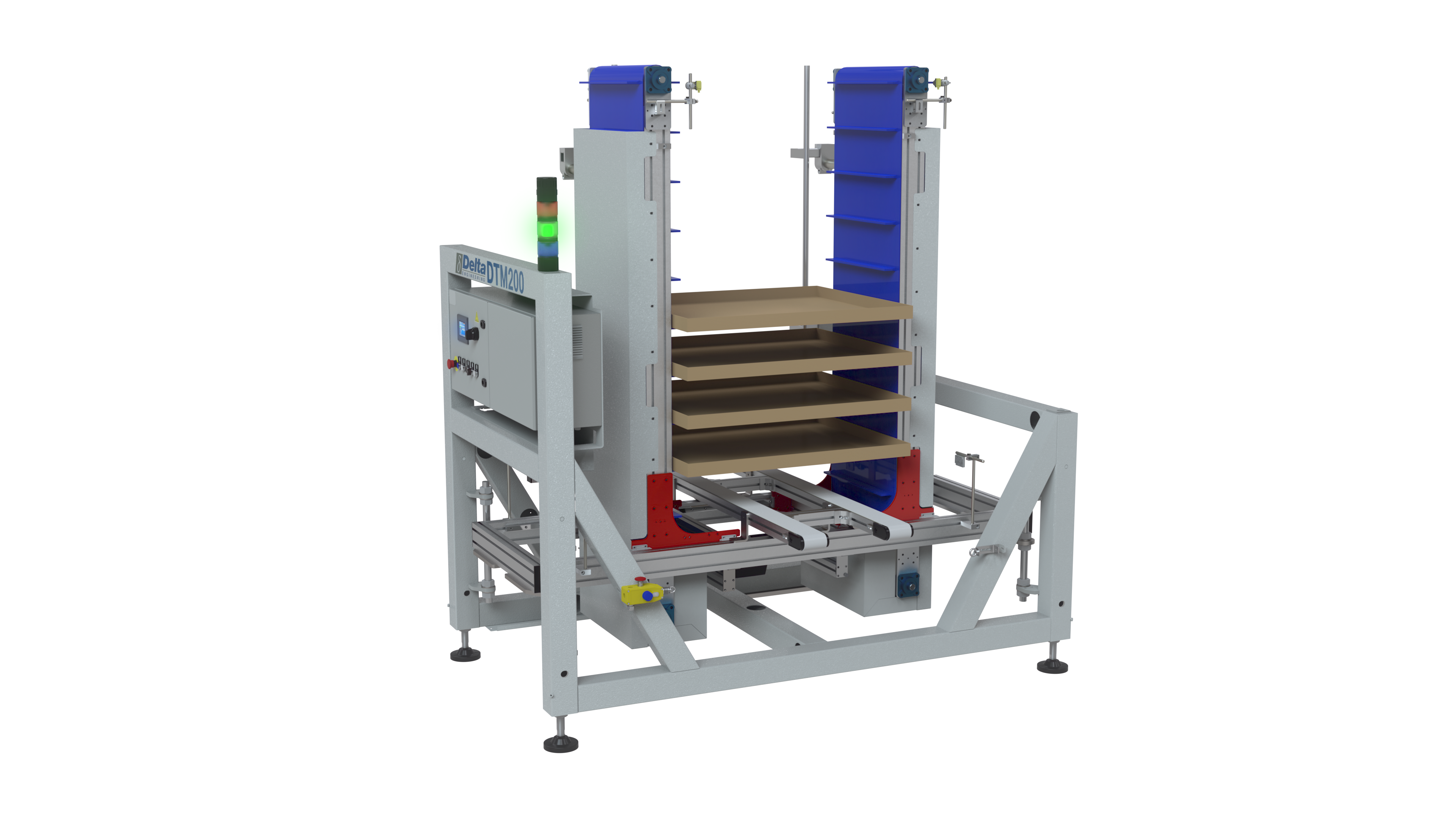

DTM200

Simple, compact tray warehouse

Need

As speeds of machines go up, there is a need for the downstream to follow, reducing labor cost.

The main purpose of this machine is to store trays, 10 pieces maximum, with a maximum height of 160 mm.

Using trays is still the most frequently used way to automate and reduce the operator intervention time. The DTM200 allows you to feed in 10 trays, which can be fed into the palletizer one by one. As a result, you can maximize the time spans between two interventions of the operator.

Moreover, the trays are stored mechanically separated, to ensure feeding in one at a time only. It drops and releases the tray on 2 outfeed belts, towards the palletizer. After all, sticking is a common problem when using trays. This can have different reasons, like humidity from cleaning, dirt, design failures, static charges…

Furthermore, the machine has a centering system as well.

This is a simple and economical version up to medium speeds.

Optionally, you can use the machine to feed top frames as well. In this way, the frame is fed out towards a palletizer or robotic stacker.

Avoid design mistakes!

Please reach out to our specialists so we can help you with your project from the early start of the design phase.

Because often, trays are wrongly designed, which has an impact on cost & line efficiency.

The machine

- Can handle trays and top frames from 800 mm (36”) to 1420 mm (56”) in all directions

- Has a centering system

- Avoids sticking by design

- Compact footprint

- Easily adjustable thanks to the open frame structure

- Integrated in lines or stand alone

OTHER VERSIONS

Tray warehouse: DTM212

RELATED MACHINES

Modular rotary palletizing and depalletizing component: DP410

Modular linear palletizing and depalletizing component: DP420