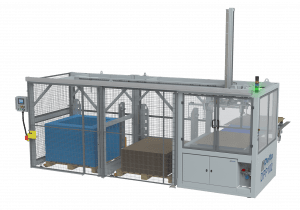

DPP102

Flat sheet, tray & top frame placer

Need

As speeds of machines go up, there is a need for the downstream to follow, reducing labour cost.

The main purpose of this machine is to place flat sheets, as well as trays and top frames.

Using flat sheets (plastic or carton sheets) is still the easiest way to automate and reduce the operator intervention time. The DPP102 allows you to feed in a complete pallet of flat sheets/trays/top frames, which the outfeed conveyor feeds into the palletizer one by one. As a result, you can maximize the time spans between two interventions of the operator.

The machine

The DPP102 has two warehouses. The gripper grabs a flat sheet, tray or top frame from the warehouse, and places it on the outfeed conveyor towards the palletizer. For top frames, the gripper grabs a sheet and places a top frame on top, so they can be fed in automatically into the palletizer.

Moreover, this unit has an anti-sticking system to ensure feeding in one tray at a time only. It grabs and releases the flat sheet in a special way to ensure this. After all, sticking is a common problem when using flat sheets. This can have different reasons, like humidity from cleaning, dirt, static charges between the sheets…

Furthermore, the machine has a centering system as well. Misalignment is typically caused by sticking: when the vacuum gripper grabs a flat sheet and the next one is partially sucked along (due to adhesion forces). As a result, the sheet often falls back onto the stack, causing the sheets to be misaligned (not neatly stacked). As the suction cups are mostly towards the middle, the gripper would obviously not detect the misalignment, so the flat sheet would be placed anyway, not aligned. This is often the cause of fallen bottles on the edges (because there’s a gap) on pallets. Therefore, the centering system is very useful to avoid this!

ADVANTAGES

- Can handle flat sheets, trays and top frames from 800 mm x 800 mm (36” x 36”) to 1420 mm x 1420 mm (56” x 56”) in all directions

- Has a centering system

- Anti-sticking system

- Compact footprint

- Flexible pallet infeed (left, right, center)

- Flexible tray outfeed (left, right, center)

- Servo-controlled high speed movements to cope with today’s high line speeds

- Different grippers possible: suction cup gripper for flat sheets, clamping gripper for wooden frames, or customized gripper

OTHER VERSIONS

Flat sheet & tray placer – with 1 warehouse: DPP101

RELATED MACHINES

You can use the DPP102 on existing palletizers or on the following machines:

Fully automatic palletizers with integrated tray warehouse: DP240, DP252

Flexible palletizing and depalletizing unit: DP420