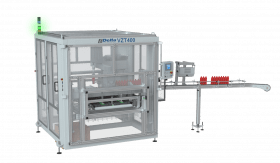

VZT400

Flexible robot packaging unit

Need

High-end cosmetic products cannot get scratched, not even slightly. However, bottles often get scratched in blow moulding machines, guiding rails, downstream, etc.

After all, some materials are extremely sensitive, e.g. glass copolymers, but PET & PP bottles as well when they are freshly produced.

For this reason, we have developed a special packaging solution which avoids scratches: the VZT400 flexible robot packaging unit.

The machine

Firstly, the machine takeout grabs the bottles and sets them down on our vacuum conveyor.

For this application, we have special conveyors with small slats. As a result, you get a highly stable bottle transport.

Secondly, the bottles are transported on this conveyor without guidings, resulting in a scratchless transport.

Then, when they arrive in the VZT400, the flexible robot measures their position, grabs the bottles on the fly, and sets them down in a tray.

Often, these trays are thermoformed and covered with a soft material, avoiding scratches again.

Moreover, the machine can work as a buffer as well to allow the bottles to cool down, and an operator can grab them later.

Furthermore, it is possible to use the machine in buffer modus as well. To this end, bottles are set on coordinates on the belt, and the flexible robot can pick them up again, inserting them back into the bottle stream.

In addition, this flexible robot can handle trays up to 800 mm wide, length according to your needs, typically 2000 mm.

In conclusion, this is the perfect solution for extremely difficult bottles!

ADVANTAGES

- You can use this flexible robot to fill preformed trays

- Flexible buffer between the blow moulder and the filling line

OTHER VERSIONS

Standard collecting table: VZT110, VZT111, VZT112

Tray packer to pack in trays: VZT210, VZT211, VZT212, VZT220, VZT221, VZT222

Tray packer to pack in trays – bottles neck down: VZT230, VZT232, VZT240