DDC200

Dynamic Data Collector Server application

What is it?

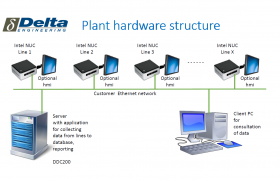

The Dynamic Data Collector Server application collects the data from the different DDC100s (Dynamic Data Collectors) on the lines.

This has several reasons. The main reason is to store and condense the data after a while.

Since the Data Collectors store many measurements, test results, etc, this represents a lot of data. For some data, however, it has no use to store them forever, like leak tester measurements. To this end, you can select and condense these data sets with the DDC200.

What can the Dynamic Data Collector Server application do?

The DDC200 will store your data in a secure, redundant way.

Namely, the data are stored in an SQL database. Furthermore, reports can be generated in a continuous way, using the standard company reporting tools.

Besides, this Dynamic Data Collector Server application is available as a virtual machine or can be supplied on a hardware server platform.

Moreover, the setup is not time-sensitive. The collecting of the data can be scheduled anytime. That is to say, independent of server reboots, restarting of PCs, etc. It does everything to avoid data loss.

Which data?

It stores data on line control. The DDC100s collect all data from the blow moulding line. For example, measuring energy consumption, cycle time, line KPIs (e.g. kWh/kg processed material), leak testing data, and much more.

Line control: IMPROVE YOUR EFFICIENCY!

In conclusion, line control is the perfect tool to monitor your efficiency and increase performance. Actually, it is not just a tool that you buy, but it is a process of awareness in the factory, empowering people, changing the mindset.

Please get in touch with us to discuss this topic in more detail.

RELATED MACHINES

Dynamic Data Collector: DDC100

Line controller