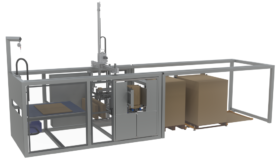

DPR200

Cardboard pallet assembly robot

Need

Pallet usage is widely spread in today’s market. Different types of pallets are available, click here for a list.

Nowadays, wooden pallets are more and more replaced by plastic pallets (returnable) or cardboard pallets, which are recyclable in the current paper or cardboard recycling stream.

After all, wooden pallets have a few downsides:

- Availability

- High transport cost (only 720 pallets fit on a full lorry, double stacked)

- Labour-intensive (double stacking, loading & unloading)

- Heavy for the operators

- Need for fumigation, because they can contain insects or other bugs. Therefore, fumigation is necessary when shipping in containers.

- Dirty, splinters, dust, etc.

- Takes a lot of warehouse space.

- …

For this reason, we have developed the DPR200: a pallet assembly robot, which allows you to produce your own cardboard pallets in-house!

The machine

This pallet assembly robot allows you to produce your own cardboard pallets in-house at a rate of 10 to 30 pieces per hour, depending on the pallet type.

So this means that you can annually produce 100.000 pallets in-house!

Moreover, it is designed to make pallets of all types, up to 56” (1422 mm) square, and anything below that. For example, it can make all typical pallets like Euro-pallets (1200 mm x 800 mm), industry pallets (1200 mm x 1000 mm), GMA pallets (40” x 48”) and American pallets (44” x 56”), etc.

Because it conceives pallets out of locally acquired cardboard, you can save on all the above points.

ADVANTAGES

- Flexibly adjustable – the machine can switch between 2 or 3 different board sizes without stopping.

- Space saving – you can produce just the number of pallets you need when you need them, so you do not have to provide storage space for your pallets.

- Compact – DPR200 has a compact footprint of 6300 mm x 2200 mm x 3350 mm (1 storage position for top plates), or 7850 mm x 2200 mm x 3350 mm (2 storage positions for top plates), or 9400 mm x 2200 mm x 3350 mm (3 storage positions for top plates).

- Safety – safety doors and guards for the infeed/outfeed ensure the safety of the operator.

- Easy to use – we designed the user interface to be very intuitive and user-friendly for the operator.

- Adjustable – positioning of bottom blocks possible according to preferences.

- Fast payback!

DPR200 with round pallet feet: