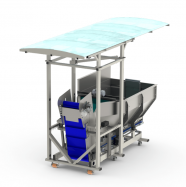

DBL110

Bottle unloading bin

Need

Normal bottle unloading bins are mostly dedicated for a specific range of bottles, like 2-10L, 50-200 ml, etc.

When we first designed the flex pickers, we encountered this issue, as our target for the flex pickers was to create a “one serves all” for the market, ranging from small bottles to 5L drums.

Therefore, we decided to create one of our own: the DBL110.

The machine

This bottle unloading bin feeds bottles gradually to the infeed of an unscrambler.

After all, unscramblers are highly sensitive to bottle jamming on the infeed: When too many bottles arrive at the same time, it often results in jamming, scratched bottles…

However, the DBL110 resolves this problem: the operators can easily empty bags, trays and pallets with bottles into the 2 m³ bin. Then, the bottles are gradually unloaded to feed an unscrambler. As a result, you avoid bottle jams!

Because the bin has an adjustable slope, it is suitable for a wide range of bottles. Whereas standard bottle bins are only for a specific bottle range.

Moreover, the infeed bin had Kevlar reinforced straps to avoid bottle deformation.

The design is in such way that that bottles are emptied completely.

Dust cover optional.

ADVANTAGES

- This bottle unloading bin is a very flexible machine allowing a wide range of products.

- Fast changeover times

- Reduces the manual labour resulting in a short return on investment

- Latest safety performance levels integrated

Standard features and options

Standard features include:

- Rugged machine with a powder coated steel frame

- Parts in contact with bottles: stainless steel

- Adaptable for a range of different bottle dimensions

- Graphical user interface with touch screen and recipes for easy setup

Options:

- Roof