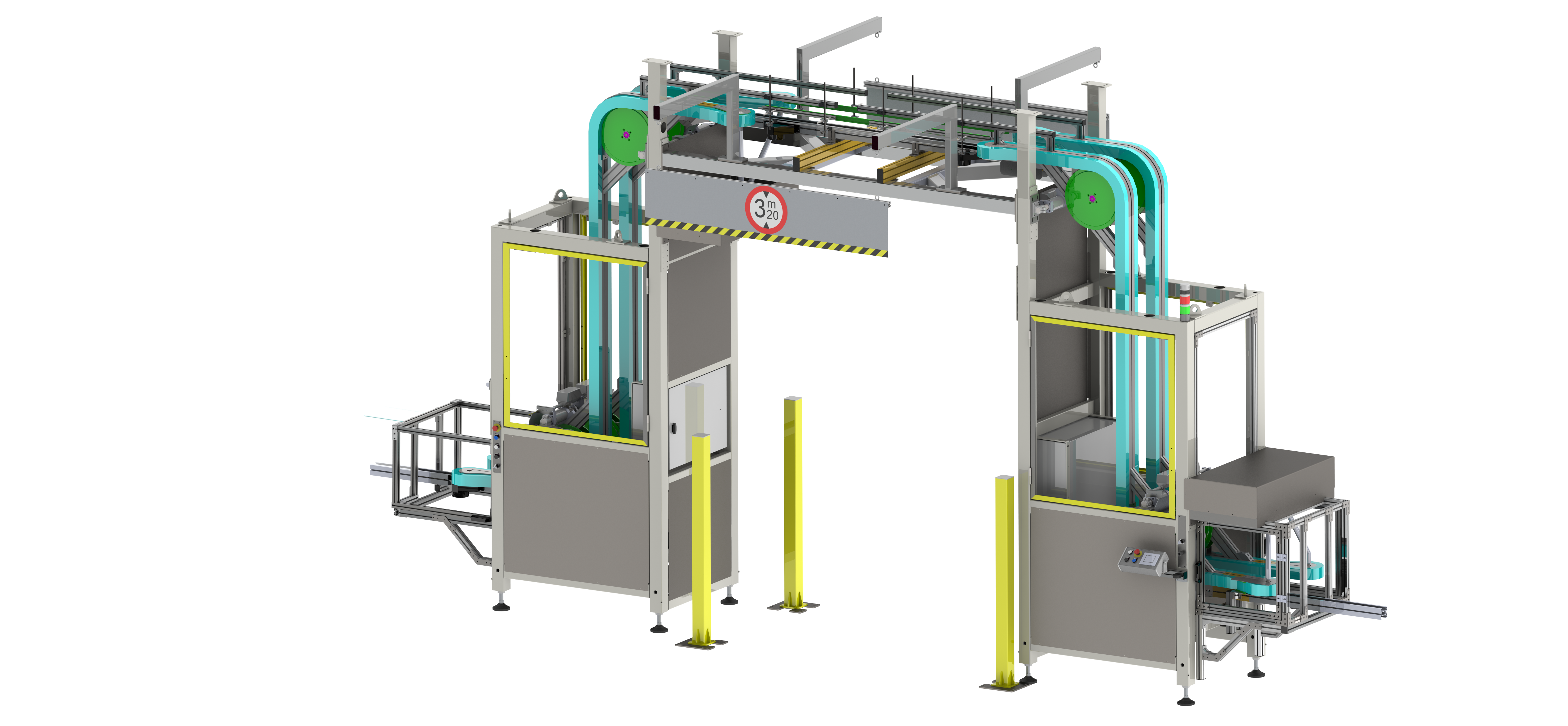

DBL200

Bottle elevator

Need

Bottle conveying lines often need to make a jump in height level.

This can be for different reasons:

- In order to convey the bottles up and down to create a passage. In this case, 2 units are necessary.

- Or, in order to move the bottles to a different floor level

- …

Therefore, we designed the bottle elevator. It is a completely shielded and safe solution to lift plastic bottles to a higher level.

The machine

The bottle elevator consists of 2 side grip conveyors, which are (optionally) electrically adjustable in width. More specifically, it adjusts the conveyors, so that they are a bit smaller than the width of the bottle. In this way, the side grip conveyors can grab the bottles and can convey them upwards, without them falling.

Once the bottles are at the top, the machine positions the bottles straight again with a 90° curve.

The exit height, finally, is configurable to suit your needs.

Moreover, this bottle elevator is completely shielded with a safety PLC with the appropriate performance level.

To clarify, the safety PLC or programmable logic controller controls the machine’s safety systems. In fact, it detects any possible fault to prevent that failures cause unsafe situations.

ADVANTAGES

- This bottle elevator is a completely shielded solution to ensure the operator’s safety.

- Includes a safety circuit with separate safety relays.

- Electric side adjustment for a quick changeover.

- In- & outfeed safety shielding, gas spring loaded.

RELATED MACHINES

Bagging machines: DB112, DB122, DB142, DB222

Shrinking tunnel: WEL110, WEL115