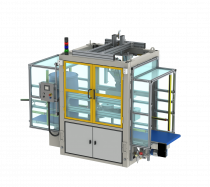

DDR200

Punching unit

Need

L-ring drums (also known as “L-ring barrels”) are plastic drums suitable for transport of dangerous goods and are often subject to the UN Recommendations on the Transport of Dangerous Goods or Title 49 of the Code of Federal Regulations.

L-ring drums have drain holes punched in the top ring. This is necessary to evacuate water when stored outside, because L-ring drums are often stored outside.

Typically, 2 – 3 holes spread around the drum diameter. Nowadays, holes are often still drilled manually, which may result in leaks. Because when drilling manually, it often happens that the operator accidentally creates leaks due to a wrong drilling angle.

Moreover, they often drill the holes even after the drum has passed the leak tester… For this reason, we have developed the DDR200 punching unit.

The machine

Instead of drilling, we have developed a punching system.

So how does this punching unit work?

A mould part, identical to the top ring shape, goes over the top, and it punches a hole.

Creating the hole in this way ensures the angle, making it impossible to create a leak.

Moreover, the punching unit creates no plastic drilling scrap, but nicely punched rounds, which are collected in a waste bucket. As a result, you can keep the machine clean.

This unit is mainly used with faster machines or in cases where customers desire multiple holes in the L-ring. In those cases, our quality center QC060 with an integrated unit is too slow. Therefore, you can use the punching unit in combination with the QC060: optionally, the DDR200 comes behind the QC060 without the integrated punching unit.

ADVANTAGES

- Checks the roundness of the drum (barrel)

- Programmable number of holes

- Recipes for quick changeover

RELATED MACHINES

Leak tester for drums (barrels): UDK060

Quality center for drums (barrels): QC060