Permanent marking on plastics

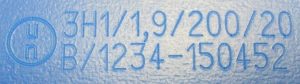

You can use these technologies to create markings directly on plastic bottles or containers, for example UN codes, manufacturing timestamps, volume markings on baby bottles, decorative markings like company logos etc.

We tested and compared different techniques: laser marking and dot peen marking (also called dot pin marking). For each technique, we made an overview of the advantages and disadvantages that we encountered during the testing.

Moreover, we tested on different colours and materials: HDPE, PET and PP, to examine the impact on the quality of the marking.

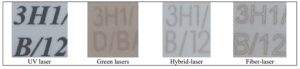

For the laser marking, we also compared different laser types: UV laser, green laser, fiber laser, hybrid laser and CO2 laser, and scored all markings on contrast and scratch resistance.

For the dot peen marking, we compared a pneumatically driven stylus and an electromagnetically driven stylus. We also tested which other factors affect the quality of markings on plastics.

Curious about our findings? You can read our full research paper with pictures by logging in in the upper right corner of this website.

When you are logged in, you will see a document below on which you can click to open it: