DXR120

Top performance large Micro and Nano CT System

Need

Microtomography is a technique that has been used for a long time already in the medical world, which most of us have encountered already in the hospital: CT scanning.

But did you know that you can use the same technique for bottles as well? Delta Engineering is now making this technology affordable for the blow moulding industry:

Microtomography allows you to:

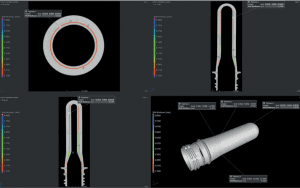

- Generate 3D drawings of products – ‘As is’: with all their characteristics and possible flaws.

In the near future, we will offer online services to calculate top load, volume, oxygen & CO2 barrier, etc (in an online platform). Moreover, it will be possible to use these data in process simulations, feeding back ‘big data’ to simulation systems. - Inspect for quality problems: for example, determining how much barrier material is present in a preform

(see picture on the right) - Improve your product analysis: for example, for weight reduction

- Look into the product: for example, to detect assembly issues:

- Is the cap closing everywhere?

- Detect internal leakage in pumping systems

- And many more!

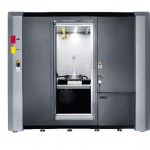

The machine

The DXR120 is a top performance large micro and nano CT system that collects complex internal and external geometry data.

This CT scanner visualizes the complete bottle with extreme precision.

As a result, you can do a fully automated quality inspection, measuring thickness, inclusions, presence of layers, etc.

Advantages of this top-performance micro and nano CT system:

- Micro and nano mechanics and resolutions

- Specialized or combined high energy (230KV) and high resolution (nano) configurations

- Ideal for in-situ scanning with easy access to the sample and test setup

- Flat panel detector or CCD camera

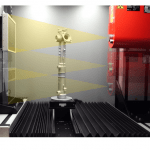

The CT scanner uses X rays to beam through an object onto a receptor plate. By doing so, it generates a picture.

It takes multiple pictures while the object is turning around. As a result, the pictures are processed into a 3D model. On this 3D model, several structural analyses and measurements can be made as well as optional CAD model export.

OTHER VERSIONS

Compact Micro CT System: DXR100

High performance versatile Micro and Nano CT System: DXR110