DTP281

Flexible digital printer for plastic bottles or containers – with 8 printing stations

Digital Printing

Digital prints can get very close to matching the extremely high quality of In-Mould Labelling (IML).

Thanks to our partnership with Shift-ID, a renowned digital printing expert with 20 years of printing experience, we can offer you digital printers for on-demand printing directly onto plastic bottles, containers or tubes, without labels.

Shift-ID’s patented digital printing technology offers significant advantages over conventional decorating methods such as In-Mould Labelling and Offset Printing.

ADVANTAGES

- No need to purchase and store high volumes for varying labels (many different SKUs) with high minimum order quantities, unlike IML

- Unprecedented flexibility for design changes and small orders – Simply print exactly what you need when you need it! This allows you to increase your product range, without the IML or offset label costs.

- Nearly zero waste!

- Extremely quick changeover thanks to product-dependent parts.

- Increased OEE: no line stoppages between different prints.

- Easy operation: any operator can operate the digital printer, without the need for printing experts.

This digital printer will allow you to make food-grade, recyclable products with unseen IML-like high quality prints on demand and in-line with the Injection Moulding machine. This technology creates new opportunities to enhance the efficiency and productivity of the injection moulding, blow moulding and thermoforming industries.

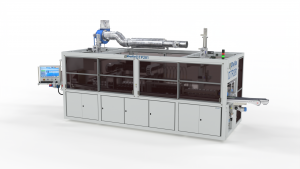

The machine

The plastic bottles or containers are fed into the machine on a chain conveyor.

The DTP281 has 8 printing stations, reaching speeds up to 3000 bottles per hour, depending on the shape, artwork and product dimensions. The digital printing stations are developed and manufactured by our partner Shift-ID.

The DTP281 can print directly on bottles or containers with a diameter of up to 100 mm at full speed or up to 200 mm every other one (half speed). When the printing is finished, the bottles or containers exit the machine on a chain conveyor.

The machine handling is completely integrated, allowing your products to be conveyed into the machine and to be fed out to packaging lines automatically.