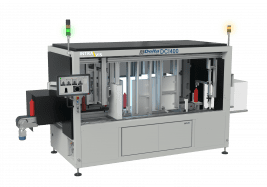

DCI400

Camera inspection unit and leak testing

Need

Space is key in factories today. However, we often see that combining machines from different suppliers takes up a lot of space due to combined machine safety distances, etc.

For example, when combining a leak tester and a camera inspection unit from different suppliers.

For this reason, we partnered up with INTRAVIS, a worldwide renowned firm in this field, to offer a compact quality control solution.

The machine

As the DCI400 is attachable to any on-the-fly leak tester from the UDK35X series, you can save space in your factory. (See machine pictures below!)

But most importantly, this camera inspection unit carries out an excellent quality inspection of plastic bottles:

- surface inspection

- bottom inspection

- neck inspection

- shoulder inspection

- contour inspection

- fill level line inspection

It can detect contamination (e.g. black spots), grab handle folds and other imperfections.

Moreover, this camera inspection unit has the complete INTRAVIS look and feel, which is important for existing customers.

Furthermore, it can be connected to their standard vision platform for registering and logging… as if it were a standard INTRAVIS machine!

In short, you get the mechanics by Delta Engineering, and the vision system by INTRAVIS.

OTHER VERSIONS

Compact economic vision system: DCI100

Advanced vision system: DCI200

High speed vision system: DCI250

Advanced vision system for containers: DCI300