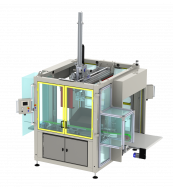

DCP200

Fully automatic case packer – per row – big boxes

Need

Case packing is a widely used solution in the US market. Case packers pack empty bottles in boxes in a neatly arranged way, either with or without interlayer sheets.

In some cases, end users are even filling their products in the box!

At Delta Engineering, we have developed different types of case packers:

- Layer types: grabbing a layer at once: DCP300

- Row types: grabbing a row at once: DCP100 or DCP200

- Semi-automatic case packer: DCP050 for low speed packing. This still involves manual labour, though.

Row types are mostly advisable for HDPE, whereas we mainly advise layer types for sticky materials like PET, PP, LDPE… As PET can be very sticky, it can cause issues in getting the last row in. For this reason, the layer types are better.

On the other hand, row types can be very useful for specific bottle types, for example conical tubes.

Conical tubes can be tumble packed in an arranged way, resulting in high bottle volume / stacking ratios. As a result, this reduces the transport cost per bottle.

The machine

Firstly, the DCP200 feeds the bottles in on a chain or flat belt conveyor. Then, it makes a row of bottles on this conveyor and a gripper grabs one row at a time. By doing this multiple times, the case packer forms a layer in the box.

It can pack bottles in big boxes, up to L 1200 mm (47”) x W 1000 mm (39”) x H 1000 mm (39”), typically used in in-house operations.

The box is fed into the machine, centered, and inclined. This inclination avoids that the bottles fall back, so it ensures that the rows are remaining in place. For this reason, this concept is suitable for simple bottles only.

Because with oval / conical bottles, there’s a risk that they will tilt over, which would make it impossible to place the next row on top of it.

However, oval bottles can be handled perfectly using our ‘Arranged Tumble Packing’ method.

Please contact your sales representative for more information!

Optionally, a box stacking device is available for the DCP200, allowing to stack multiple layers of bottles on top of each other.

This is a flexible machine which is designed for fast changeover.

ADVANTAGES

- Rigid construction

- Suitable for stable bottles

- Flexible machine which can pack a wide range of products

- Fast changeover times

OTHER VERSIONS

Full automatic case packer – per row – small boxes: DCP100

Full automatic case packer – per layer: DCP300

Semi-automatic case packer – per layer: DCP050