Line controller

What is it?

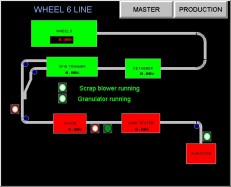

Our line controller is a central PC/PLC controller, which controls all drives and reads inputs from different sensors (line/machine), etc.

In this way, it allows supervision of the parameters and operation of machines and production lines.

In this line controller, we have standard software for simple control as well as advanced neural algorithms for complex lines.

What’s the difference between PC and PLC?

– To clarify, a PLC or Programmable Logic Controller is an industrial digital computer which controls manufacturing processes. It is highly reliable and robust, so it is suitable for harsh industrial environments.

– On the other hand, you have PCs or Personal Computer-based controls for machine automation. They implement more complex software, so they can process more data faster.

Our line controller is also known under the name DLCXXX.

What can line control do?

With today’s increasing speed and line complexity, line control becomes more and more important.

Our line controller controls the flow of bottles, the transitions and bump back effects on bottles, and it avoids jams and fallen bottles.

As a result, line control ensures higher line efficiency!

Moreover, we also have a Dynamic Data Collector which offers many possibilities to improve your line efficiency. Click here to discover some of the applications!

Offline simulation

On high speed lines, you can use line simulation to test complex lines, see how the software behaves, debug…

Line simulation is a PC software tool. Its PC program, designed to simulate lines, simulates the PLC’s inputs and outputs without the PLC being aware of it. This allows us to test the software as if it were real. As a result, complex lines can go online pretty quickly without the usual hiccups in software.

With today’s increasing speeds and complexity, a line controller is becoming a necessity rather than just a nice tool.

ADVANTAGES

- Automatic starting & stopping of the entire line in order to save energy and reduce maintenance.

- Energy measurement system: optional

- Possibility to track errors (e.g. flow reduction in moulds…)

RELATED MACHINES

Dynamic Data Collector: DDC100

Dynamic Data Collector Server application: DDC200