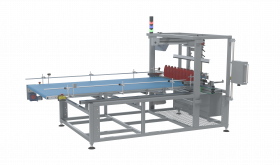

DBT232

Buffer table

Need

Buffering is very important to have a highly efficient packaging line. The need is increasing with today’s increasing speeds of packaging lines.

This buffer table makes the line immune to micro stops and operator response times. As a result, you increase line efficiency.

You can use it in front of trimming machines, to avoid stoppages.

Or, you could also use it as an extra buffer in front of labellers, to cope with stoppages (when changing the label rolls). However, it would be better to use the DBC202 or DCT213 for that, because those have a cooling function as well.

How does it work?

This buffer table is an automatic buffer solution for empty accumulating bottles.

The buffering depends on the downstream. That is to say:

A. If the downstream is free and the buffer is empty, the DBT232 will pass the bottles without forming a row in advance.

B. If, on the other hand, the machine contains buffer or in case of a full downstream, the DBT232 will make rows before the machine.

Then, this row will enter the machine:

- In case of a free downstream, the row will pass through the machine.

- In case of a full downstream, the buffer table will buffer the row. As soon as the downstream is free, the DBT232 will un-buffer his buffer conveyor. After clearing his buffer and if the downstream is free, the bottles will pass through the DBT232 without forming a row.

The machine

- This buffer table is for stable, square, accumulable bottles only.

- Its buffer conveyor is 1200 mm wide and has a configurable length, depending on the available space.

- Furthermore, it functions according to the LIFO concept (last in, first out).

- Typically, it is used between blow moulding & filling lines, because of its ability to feed in bottles externally.

- Because of the control system, the buffer table can work as a buffer only, switching to it when needed. In other words, you cannot use it as a cooling conveyor.

- Optionally, you could use it to feed in ‘other’ new products on the conveyor.

- Additionally, it is available with adjustable guiding and top covers to ensure bottle integrity.

ADVANTAGES

- Buffer system

- Compact footprint

- Expandable in length

- Short downtimes of other equipment will not affect the production speed. This results in increased line OEE: Overall Equipment Effectiveness!

- Fully automatic operation

- The buffer table has a short changeover time. All the parameters can be loaded from recipes.