DBC202

Buffer conveyor

Need

Buffering is very important to have a highly efficient packaging line. The need to buffer is increasing with today’s increasing speeds of packaging lines.

So how does this buffer conveyor increase line efficiency?

- Most importantly, by making the line immune to micro stops and operator response times!

- Moreover, it resolves labeling issues on HDPE lines (like bottle shrinkage), as well as issues with trimming machines or palletizers (frequent stoppages)…

As a result, it improves your OEE or Overall Equipment Effectiveness.

But what does OEE mean?

In short, OEE is a way to measure how productive your manufacturing is. By doing so, you can use this knowledge to improve your production processes!

OEE takes into account all losses of production. These losses can belong to one of three categories:

- Availability:

This measures production losses related to downtime. In other words, when the process stops running for some time. Because of changeover time, machine not running because of no sales, etc. - Performance:

This measures production losses related to reduced speed. Because of slow cycles and micro stops. But our buffer conveyor DBC202 avoids such micro stops! - Quality:

This measures production losses related to produced units that you cannot release. Because the produced parts are defect or need rework.

For more information on OEE, you can check the following links: Overall Equipment Effectiveness or OEE.com.

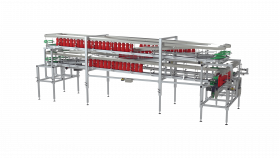

The machine

Length of this buffer conveyor: 36 meters.

Thanks to its control system, the DBC202 can work in different ways:

- As a buffer, only switching to it when needed.

- Continuous troughput, buffer conveyor.

- Continuous troughput, cooling conveyor.

In fact, the speed is adjustable to switch between cooling & buffering.

Additionally, we can add multiple loops, single chain, to increase the capacity.

Furthermore, the DBC202 is available with adjustable guiding and top covers to ensure bottle integrity.

ADVANTAGES

- Buffer conveyor with a modular system: cooling & buffering

- Compact footprint

- Expandable

- Increased line OEE!